- Home

- About Us

- Services

- Coatings and Linings Inspections

- Corrosion and Condition Assessment

- Advanced & Conventional NDT

- UAV RPAS and ROV Survey Inspection and Imaging

- Cathodic Protection

- Rope Access Inspection

- Drone Photography and Videography

- Laser 3D Scanning

- Coatings Inspection Equipment Calibrations

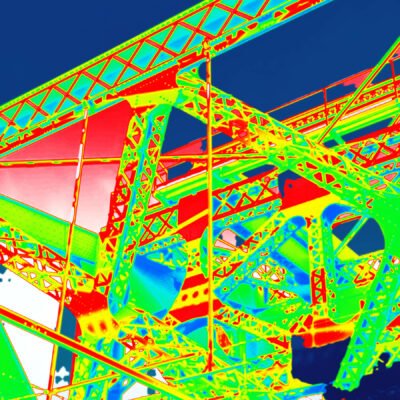

- Thermal Imaging Inspection

- Contact